“Listen, your gimbal is knocking ... Hand it over for repairs, otherwise it will end badly,” the heroine of the film “Moscow Does Not Believe in Tears” received such a recommendation from her boyfriend. However, with the malfunctions of the "cardan", scientifically called the cardan shaft, the motorist can often cope on their own, without resorting to the help of a workshop. Why is this unit so important and what is needed for its repair in "garage" conditions - more on that later.

Purpose of the propeller shaft

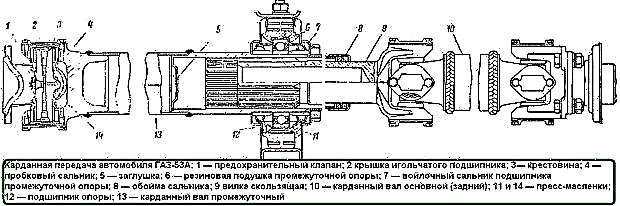

In principle, front-wheel drive cars do not need a cardan. Their engine transmits revolutions to the drive wheels through completely different transmission elements. But cars, in which the rear wheels are leading or all four, are nowhere without a cardan.

In the first case, this part connects the gearbox with the rear axle gearbox, and in the second, there are usually three such elements at once. One of them connects two gearboxes: a gearbox and a transfer case, the other two transmit revolutions from the latter to the axles.

By the way, the car, which, according to the ladies' man from the picture "Moscow does not believe in tears," knocked the cardan, was a rear-wheel drive VAZ 2103.

Can the cardan knock

Some car enthusiasts, analyzing the episode from the mentioned film concerning the alleged malfunction of the driveshaft, in the comments express my thoughts on this topic:

- The splined propeller shaft with an elastic coupling may well knock. This is especially audible when crossing road irregularities and potholes at medium and low speeds.

- A worn gimbal vibrates rather than knocks.

- The propeller shaft is generally not prone to knocking.

In truth, the gimbal does indeed vibrate and sound. In modern machines, these disadvantages of the unit are perfectly handled by highly effective noise and vibration isolation means. However, not always.

Cardan imbalance

If the vehicle's speed gain is accompanied by strong vibration of its body, then this is a sure sign of imbalance in the propeller shaft. A malfunction of this kind can damage not only this unit, but also the entire machine, which is fraught with expensive repairs.

After all, an unbalanced universal joint increases the wear of parts such as the driven shaft of the gearbox and bearings of the gearbox shank flange. Moreover, a malfunction of the shank can cause an emergency while driving, the consequences of which are unlikely to please the motorist.

Well, you can find enough reasons for imbalance. Most often, the following manifest themselves:

- errors during the initial assembly of the propeller shaft;

- incorrect fastening of parts;

- low quality of the materials involved;

- too much load on the shaft;

- mechanical deformation of parts, for example, due to an accident.

Balancing the propeller shaft

Vibration in the car cannot be ignored; at the first sign of such a malfunction, you need to start fighting it. For example, by balancing the propeller shaft. This expression is widely known among motorists.

You can "adjust the gimbal" yourself, even without having the expensive equipment used by the car service for such work. But for those who undertake this process, it is desirable to at least approximately understand its essence. In general, balancing is not particularly difficult, although it can take a long time.

For its implementation, you will need an inspection pit from which you can get to the cardan of the machine. A number of weights with different weights will also come in handy for wheel balancing. Electrodes or small lead cells are also suitable as counterweights. The balancing of the gimbal itself is performed as follows:

- The propeller shaft is halved in length.

- The cardan is conventionally divided across into four equal sectors. There can be 8 or even more of them if the motorist has enough enthusiasm and a lot of free time.

- A thirty-gram weight is attached to the surface of one of the gimbal sections. It should be fixed securely, but so that later it can be removed.

- The cardan is tested by driving a car on a flat road and determining the degree of vibration.

- If vibration persists, and not all options with placing a weight on the shaft have been tried, the car is returned to the garage in the pit, and the balance bar is transferred to another section of the cardan.

- The test drive is repeated.

This cycle should be repeated until vibration is eliminated in the vehicle or its minimum level is reached. Then, by an experimental method, the optimal mass of the used balancer is selected, which can also contribute to the cessation of the shaking of the car body.

After determining the weight of the weight, it should already be rigidly fixed on the surface of the cardan. For example, using an electric welding machine. If the auto repairman does not have one, then you can apply "cold welding" or tighten the counterweight with a metal clamp.

Shaft geometry violation

The most durable components of the cardan are its cylinders, made of steel that can withstand significant loads. As a rule, such parts are designed for a mileage of about half a million kilometers. But even these elements can be deformed, for example, in the course of overcoming any irregularities by the machine or as a result of breakage of the hinges located along their edges. Severe vibration from the bottom of the vehicle when driving is a sure sign of a cardan problem.

Some "magicians" advise to level the dents on the gimbal using a sledgehammer. However, insufficiently high-quality performance of such work can also lead to an early breakdown of the crosses. Therefore, instead of a heavily deformed cardan, it is recommended to immediately install a new one, which should then be balanced. The price of this assembled unit starts at about 1300 rubles.

Cardan weaknesses

Most often, hinges, crosses and bearings break at the propeller shaft. Mostly due to wear and tear. As a rule, the listed parts are designed for a mileage of 60-70 thousand km, but it is likely that it will be less. This value is influenced by:

- features of the car's transmission;

- type of machine drive;

- product quality;

- driving modes;

- travel conditions.

Sounds or tremors that are unusual for a working propeller shaft indicate a malfunction among its hinges, bearings and crosspieces. Especially if knocks or clicks are heard in the opening of the ride or when changing speeds.

The aforementioned components of the propeller shaft are recommended not to be repaired, but to be replaced with new ones in case of heavy wear. Moreover, such products are quite easy to install and are relatively inexpensive. Estimated prices for them are as follows:

- cardan joint - from 160 rubles;

- cardan shaft cross - from 280 rubles;

- cardan bearing - from 300 rubles.

A car enthusiast with the necessary skills can replace such elements of the propeller shaft on his own. For those who are not "experts" on this topic, it is better to entrust the process to the masters of the car service.

Depressurization of hinges

Another malfunction typical for the universal joint is the depressurization of the protective shells of the ball joints. When such a casing wears out, a hole is formed in it, through which transmission oil can pour out. If the amount of this lubricant is insufficient, the joints will not be properly lubricated, which will lead to their rapid wear due to increased friction.

Traces of oil under the ball joints of an idle car indicate such a breakdown, which is corrected by replacing the leaky covers with new ones. Prices for such protective covers start at 120 rubles.

Cardan repair tools

On the modern market there are many offers for the sale of equipment for the repair of the cardan shaft. Basically, it is designed for car services, but private motorists, if they wish, can install some device from this series in their garage. For example, for more accurate balancing of the universal joint or to facilitate the process of assembly and disassembly of this unit.

Such equipment includes stand R-223, designed to repair not only cardan shafts, but also steering controls. In the course of modernization, this "workbench" received a smaller size and a reinforced tabletop, capable of withstanding a weight of up to two tons.

The device is equipped with its own lighting, as well as a perforated screen and a drawer for tools. The cardan to be disassembled is installed on a special stand, fixed with a vice and by means of a hydraulic press equipped with a pressure gauge, the bearings are removed from the forks. The unit price is about 136 thousand rubles.

For a comprehensive balancing of multi-section cardan shafts, the Balcom-4 unit will be very useful. With his participation, the entire process, including the determination of data on the weight and the location of the correction weights, is carried out automatically. The results of the adjustment made are saved in the archive, remaining available for printing. The price for the complex in the basic version is 72 thousand rubles.

If you need to express the shaking of the gimbal in a numerical equivalent, then the Vibrokom-1 device working together with a computer will help. The sensors of this device are based on the GY-61 MEMS accelerometer modules. The basic configuration of the unit includes two vibration transducers, a photoelectric phase angle detector, a USB block, and a USB stick with programs. The price of the complex is 12 thousand rubles.

Conclusion

The cardan knocks or vibrates - it still needs to be repaired. In a car service, balancing will cost about 3-5 thousand rubles, in your own garage - as they say, “cheap and cheerful”. But for high-quality adjustment of this device, expensive equipment is usually required, which is not at hand for every motorist. So the driver of the "troika" from the movie "Moscow Does Not Believe in Tears" was right about something.

|| list |

- Purpose of the propeller shaft

- Can the cardan knock

- Cardan imbalance

- Balancing the propeller shaft

- Shaft geometry violation

- Cardan weaknesses

- Depressurization of hinges

- Cardan repair tools